- Engineered Transport Equipment

- Pneumatic Conveying Systems

- Aftermarket Parts and Service

- Careers

PTO Grain Vacs

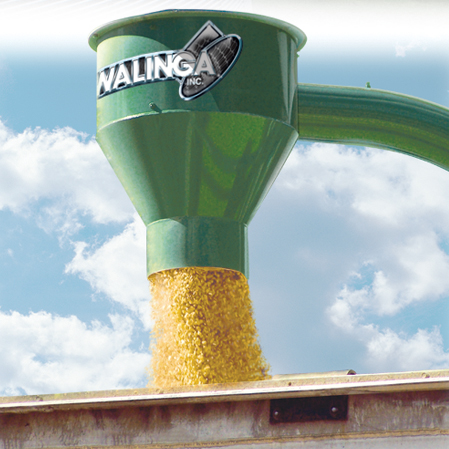

Heavy Duty Discharge Cyclone

The Agri-Vac's cone shaped receiver is designed for minimal resistance to material and airflow. Grain and air are separated in the receiver. Material flows into the rotary valve and the air moves on to the blower, which then pushes material out of the valve into the bin or truck. No filters or screens to cause plug-ups or freeze-ups.

Secondary Precleaner

Walinga's dust separator Pre-Cleaner device greatly reduces premature wear of the blower as the result of abrasive dust-laden air. Our Pre-Cleaner does not use filters or other bothersome and costly methods. Minimal maintenance is easy and fast. Product quality is maintained, in fact may be improved as the result of a natural cleaning action during transfer.

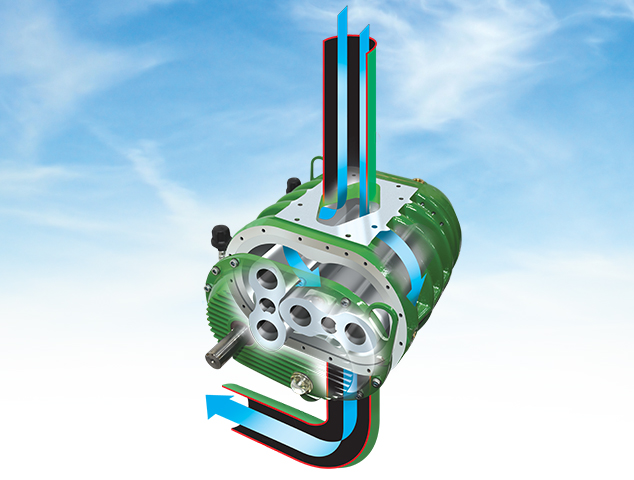

Walinga Hardened SRT Blower

You already know pneumatic conveying systems move bulk product on a cushion

of air. Walinga SRT blowers create the pressure that drives that work. Examining every facet of a blowers construction, Walinga engineers realized that by altering the structural design of a standard blower casing they could lower the amount of sound produced. Heavy-duty equipment makes noise, everyone knows that, but reducing sound production actually transfers otherwise lost energy back into the moving parts. Less vibration means less wear, less mechanical stress, better performance and a lot less noise. Add to that Walinga's proprietary Hard Coating which eliminates premature wear, ensuring a much longer life than unhardened blowers.

WALINGA'S Proprietary Hard Coatings

Experienced in the manufacturing of feed and grain equipment, Walinga is first for quality. Walinga blowers are fabricated from alloy castings that facilitate hardening. Walinga's proprietary Hard Coating process out-performs chrome hardened finishes. The process eliminates premature wear from abrasive dust ensuring a much longer life than unhardened blowers.

ALL INCLUSIVE TWO YEAR WARRANTY

Walinga endeavors that new equipment be free from defects in material and workmanship. The warranty period is either two years from purchase or 500 hrs. of operation, whichever occurs first. Full terms and conditions are available from Walinga or your local Walinga dealer.

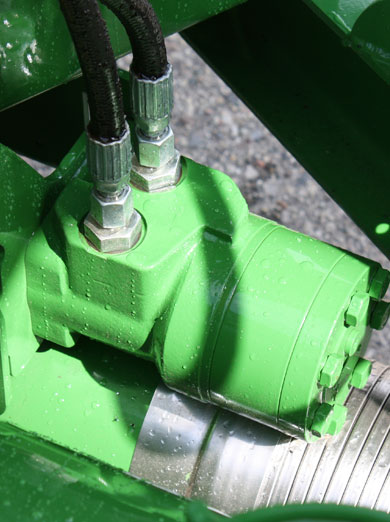

Specialty Parts are a 'Snap...'

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. If you don’t see the component you require, our engineers can make it.