Ultra-Veyors have been utilized in drying and storage facilities around the world for years. The Ultra-Veyor AG (Agricultural) and IND (Industrial) systems unique characteristics are now used in seed treatment and conditioning facilities, hemp processing, fish farms and aquaculture, chemical/fertilizer manufacturing, feed and fuel pellet manufacturing, food processing, and even breweries. Perfect anywhere dry bulk combinations of various weights and sizes need to be transferred.

It’s becoming a mantra to Walinga’s pneumatic conveying systems. Clients from around the world have worked with Walinga to produce bulk transfer solutions of varied complexity. Combine Ultra-Veyors with a network of diverter valves and pipe bulk to multiple bins. New installs or retrofits, simple transfer solutions or large scale computerized bulk mixing and distribution networks, with an Ultra-Veyor system almost anything is made possible. You’re invited to call WALINGA to discuss your application requirements.

It’s always nice to plan ahead and avoid expensive upgrades. The Walinga Ultra-Veyor system is so flexible, easy to install or retro-fit that you can add to your system as your business grows. Choose from an extensive selection of options and specifications to perfectly match your current business demands and keep those hard earned dollars in your pocket.

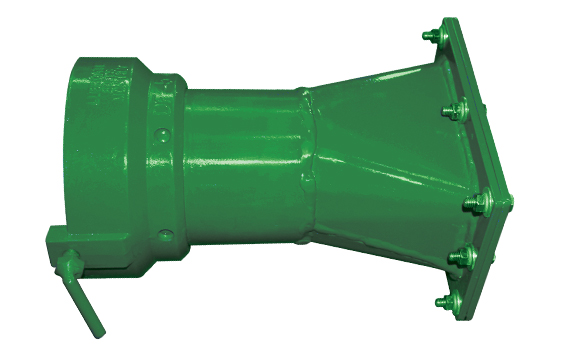

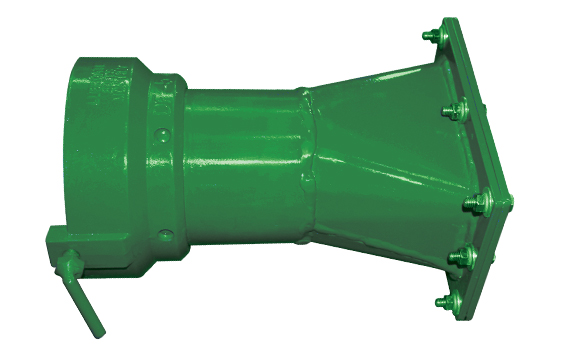

The Walinga Diverter Valve, installed initially or as a facility grows, is a popular addition to the Ultra-Veyor pneumatic conveying system. Manually operated the diverter valve assembly lets operators easily divert blown product towards up to six bin destinations. Daisy chain diverter valve assemblies when more than six destinations are required.

The Walinga Smart-FloTM , a Variable Frequency Drive System, utilizes various sensors to monitor flow rate in real time. Motor speeds are constantly tuned to maximize transfer capacities while reducing energy costs and minimizing bulk damage.

Click here for Ultra-Veyor with Smart-Flo AG

Ultra-Veyor conveying systems are powerful and with power comes responsibility. Walinga’s Programmable Logic Controller (PLC), the brain of the SMART-FLO system, constantly monitors, analyses and responds to sensor feedback. Programmed by Walinga engineers experienced in customer specific bulk characteristics, SMART-Flo targets peak performance with minimal energy consumption or bulk damage.

Can be customized to be installed with any common programmable VFD

Completely self-contained system that can be run independent of an input system such as a grain dryer.

Designed for maximum efficiency and minimal grain damage the housing is precision machined from a cast iron shell for unequaled performance. The 10 vane fabricated steel rotor has hardox steel adjustable tips for longer life. Walinga’s latest innovations include the modification of the inlet and outlet ports with flow contours for maximum capacity. To minimize grain damage, a special rotor wiper levels the pockets. The entire assembly is driven by an electric driven gear box with chain drive to airlock. Ultra-Veyor systems can be customized to fit your grain or bulk handling needs.

Click here for Airlock Specifications

Experienced in the manufacturing of feed and grain handling equipment, Walinga is first for quality. Walinga blowers are fabricated from special alloy castings that facilitate hardening. Walinga’s proprietary Super Hardened Coatings process out-performs chrome hardened finishes. The hardening process eliminates premature wear from abrasive dust, ensuring a much longer life than unhardened blowers.

Click here for Blower Specifications

Walinga’s DUSTLESS Bin Filter (above) and DUSTLESS Cyclone solutions (below) offer several benefits, including maintaining EPA dust emissions permit compliance and adhering to NFPA and MOL workplace dust standards. Both promote cleaner and healthier work environments by reducing dust emissions. Enabled storage of powdered products in silos and bins utilizing pressurized pneumatic conveying lowers maintenance costs through self-cleaning filters and a compact and easy-to-operate design. Components are weather-resistant for outdoor use, simpler to install and maintain when compared to traditional baghouse venting systems. Healthier, flexible Walinga pneumatic systems for a more damage free, cost effective comprehensive conveying solution.

Seeing is believing, book an onsite demo now. Following strict COVID Safety protocols, a Walinga representative will schedule a site visit with an Ultra-Veyor demo unit in tow. Witness for yourself the ease of operation and power of the Ultra-Veyor SMART-Flo system in action transferring your own bulk commodities. Walinga, tough to beat in the long run.

Call your local Walinga representative to book!

Walinga endeavors that new equipment be free from defects in material and workmanship. The warranty period is either two years from purchase or 500 hrs. of operation, whichever occurs first. Full terms and conditions are available from Walinga or your local Walinga dealer.

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. If you don’t see the component you require, our engineers can make it.