Designed to National Fire Protection Association standards, Walinga’s Air Purge self-cleaning filter technology reduces explosive risk, risk of fire, maintenance time and costs while promoting a cleaner, healthier work environment. Effectively a lossless system it reduces the risk of rodent infestation.

Although not identical twins, the Walinga Air Purge Vacuum Conveying Systems and Walinga Ultra-Veyor Push systems share the same Walinga DNA. Both systems utilize high performance Walinga Blower and Airlock components. Deciding whether installing a push (positive pressure) system or pull (vacuum pressure) is typically dependant on the application. A Vacuum conveying system minimizes dust and provides multiple drop points for clean up accessories or various production line integrations. A push system like Walinga's Ultra-Veyor line efficiently moves bulk over great distance and elevation with minimal damage. All Walinga pneumatic conveying systems are covered by Walinga's Two Year / 500hr. Warranty*. Choose from online chat, person to person or dealer support to take advantage of Walinga's expertise. They are ready to help determine which pneumatic conveying system is best for you. Remember, customers benefit from Walinga's extensive support network before, during and after an installation. Owning a Walinga includes ONSITE Service. Trained service technicians, tools and parts delivered right to your facilities door**.

*Full warranty terms and conditions are available from Walinga or your local dealer. **Geographic restrictions may apply.

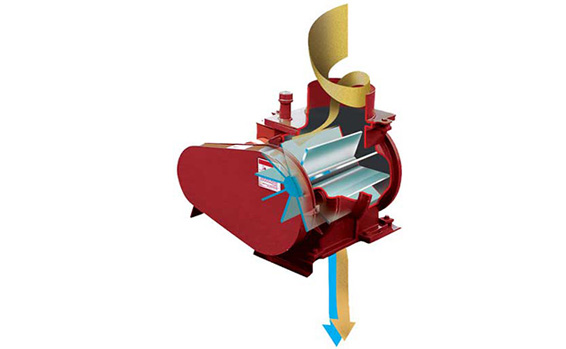

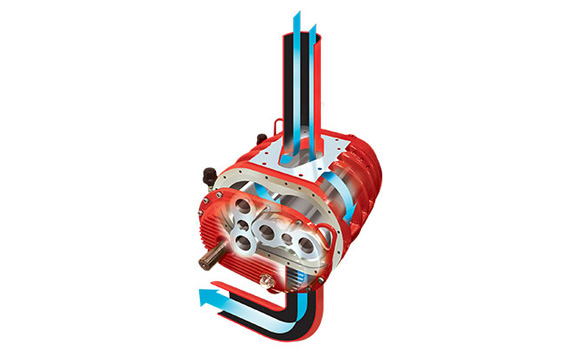

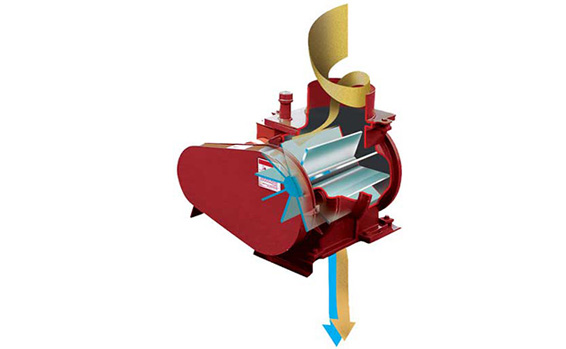

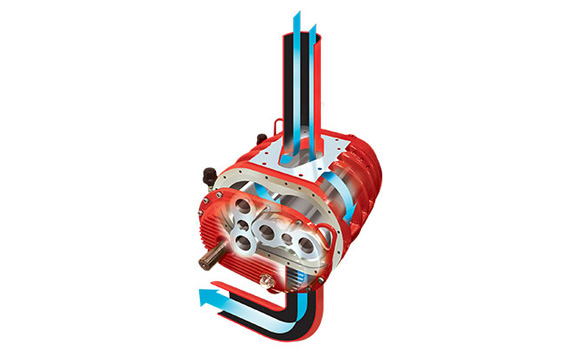

Walinga Hard Coated SRT Blowers are manufactured to exact specifications and quality control standards. The housing, end plates and impellers are precision machined.

Gears and bearings are "splash lubricated". For Vacuum applications, Walinga blowers operate at very low rpms extending the life of the blowers.

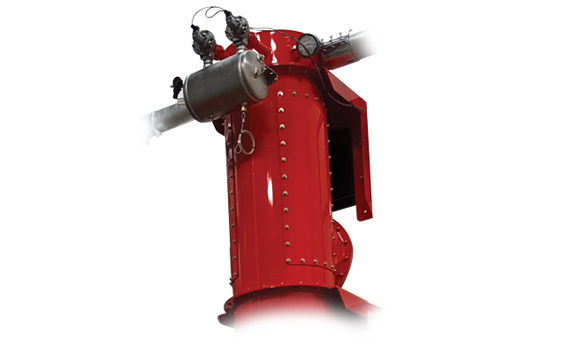

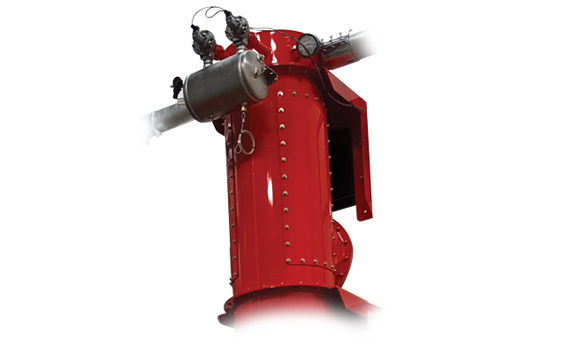

The Walinga Air Purge Primary Cyclone combines three traditional components, the primary cyclone and bin, a secondary cyclone and bin plus filter canister into one integrated Air Purge Primary Cyclone unit.

One component replacing three means simpler installation on a smaller footprint with far less maintenance.

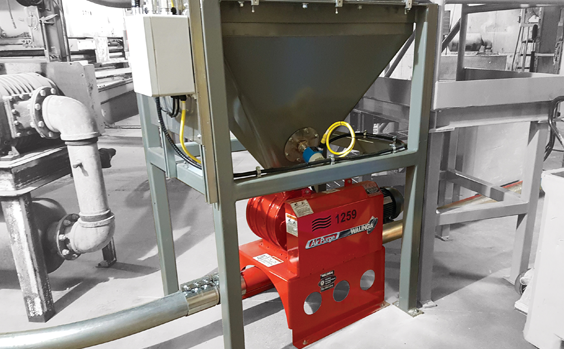

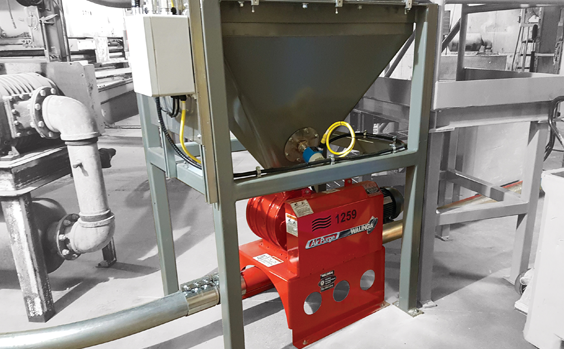

Install Walinga's scalable vacuum conveying systems pretty much anywhere you can pipe. From floor to floor and building to building customers may opt for outdoor airlock and blower package installation. The units are built to withstand the elements and an outdoor installation helps maintain minimal interior sound levels.

Design and install the system yourself. Manufactured to ISO 9001:2015 standards, parts always fit as intended, promising frustration free assembly and installation. Remember, Walinga support is always available. Tasked with simple direction, or designing turn-key systems, Walinga engineers help ensure installations are a breeze.

Is a Walinga Vac System the right choice for your transfer, dust or product recovery? It's easy enough to find out! We'll come to you. A technical representative with a full-functioning Walinga Central Vac System will visit your site, demonstrate the system with your actual bulk product and work with you to develop a system keyed to your specific needs. Call your nearest rep to arrange demo!

Walinga engineers work with you, from site inspection thru design and fabrication. Installations are a breeze. Even after installation, Walinga support remains only a call or click away. The Walinga ONSITE Service now delivers service technicians, tools and parts right to your facilities door. Some geographic restrictions may apply.

Walinga’s entire pneumatic conveying product line is powered by an all inclusive two year warranty. Walinga support doesn’t begin or end with our warranty. Walinga engineers are on hand to help plan for your facilities immediate and future needs. Walinga expert assistance will help design the ideal system as well as train operations and maintenance staff ensuring your equipment delivers peak performance for years to come.

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. If you don’t see the component you require, our engineers can make it.