Partitions manage animal proximity and density; open air ventilation systems, moving blinds and access to water (drinking nipples, water misters) minimize animal stress during transport. Specify 2, 3, 4 or 5 levels, dependant upon usage. (Weaners, Feeders, Market, Breeding Stock). Every component is resolved to withstand the demands of continuous hard use while maximizing animal welfare and bio security.

Everything you've come to expect from Walinga and more. Galvanized chassis optimize strength and durability. Look above the chassis and it's all aluminum construction. Lighter stronger construction ensures Walinga AWT trailers deliver returns for the long haul, while ensuring fuel efficiency now. Walinga endeavours to source and or manufacture AWT specialized animal transport components within North America. The combined years of Walinga transport and Walinga customers' animal transport experience has defined the best practices in animal welfare during transport, biosecurity and durability.

Passive ventilation by manually controlled curtains/blinds helps prevent animal overheating, hypothermia or dehydration and helps to lower animal stress.

Both of the Walinga Revolution AWT (Animal Welfare Transport) LIFT/RAMP trailers feature many user proven components utilized in Walinga's established line of bulk transportation equipment. Combining sixty plus years of Walinga transport manufacturing with years of live animal transport customer expertise ensures equipment is best of breed. The evolution continues. Walinga partners with customers, is engaged with regulatory bodies and continually invests in ongoing R&D to ensure components meet or exceed industry and customer expectations. Customers are unique and for those circumstances that require extra features Walinga offers a suite of options. When customers require specifications beyond current offerings, customers need only ask. Units are completely CAD resolved before production begins, each unit being manufactured to exacting customer specification.

Upgraded blinds are available and are usually combined with remote controlled electrically driven motors that can also be automated to adjust trailers climate.

Walinga manufacturing is entirely CAD driven, this means every customer unit produced exists electronically before beginning production. Customers are encouraged to specify their perfect unit with any the features they may require.

AWT Revolution Trailers are standard equipped with functionally placed LED task lighting. Many customers have their own unique requirements and will specify additional lighting. Walinga, partnered with an industry leading transport lighting manufacturer, provides near limitless, proven robust, custom lighting solutions.

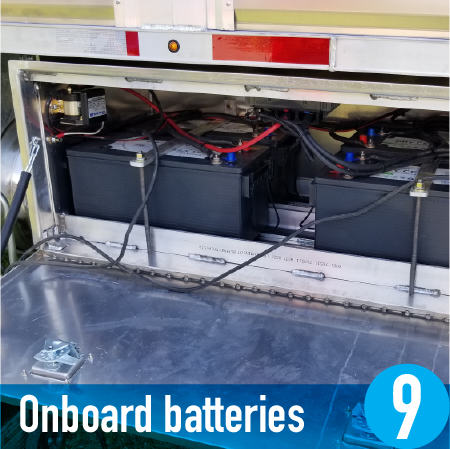

Keep components clean, dry and accessible. Walinga utilizes continuous custom wire looms in most applications. Cabling is run inside aluminum tubing as well, every protection possible to ensure wiring isn't damaged by exposure, repeated flex or vibration wear. Depending on the box, LED interior cabinet lighting comes standard. Customers often add further LED lighting throughout other lesser used boxes for convenience.

Not all climates are created equal. Modify Walinga's AWT Revolution trailers to add as many fluid reservoir tanks as your cargo and climate demand.

Interiors are designed with animal welfare in mind. Slip resistance floors and reasonably sized 'social' spaces keep animals comfortable. Smaller groupings means less injury with sudden stops. Tremendous passive ventilation exists through extensive wall openings, which can be further complimented by optional remote controlled forced air systems. Standard curtain wall optional upgrades include electrically operated UHMW panels that shut out harsh weather elements or open to lower animal stress due to heat.

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. Walinga's ISO 9001:2015 certifications apply to all North American Walinga facilities. If you don’t see the component you require, our engineers can make it.