- Engineered Transport Equipment

- Pneumatic Conveying Systems

- Aftermarket Parts and Service

- Careers

Blower Sales AMPS

FEATURES

Walinga pneumatic conveying equipment is built upon continuous innovation and product improvement. Integral to our systems performance are the combinations of various sized precision-built blowers and airlocks. Walinga blowers are available in sizes to meet the most demanding applications. Stocked component parts like pressure relief valves or grapple loops may be added to suit your manufacturing or application process. Walinga manufactures its blowers in-house. Customers are encouraged to work with our engineers to develop the best solutions possible. Bolt patterns can be modified to match existing plenums or Walinga can CAD manufacture plenums unique to a customer’s specifications.

Walinga Hardened SRT Blower

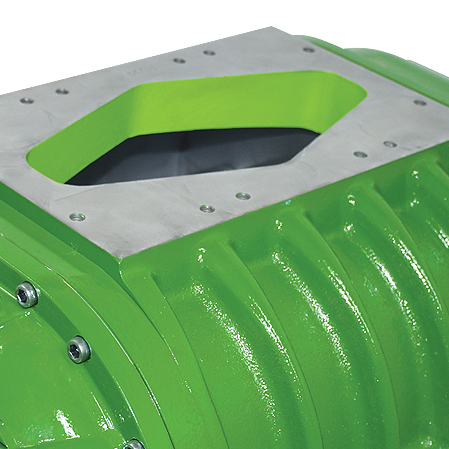

You already know pneumatic conveying systems move bulk product on a cushion

of air. Walinga SRT blowers create the pressure that drives that work. Examining every facet of a blowers construction, Walinga engineers realized that by altering the structural design of a standard blower casing they could lower the amount of sound produced. Heavy-duty equipment makes noise, everyone knows that, but reducing sound production actually transfers otherwise lost energy back into the moving parts. Less vibration means less wear, less mechanical stress, better performance and a lot less noise. Add to that Walinga's proprietary Hard Coating which eliminates premature wear, ensuring a much longer life than unhardened blowers.

ONE SIZE DOES NOT FIT ALL

Walinga manufactures a wide range of blower sizes. Evolved over years of use in proprietary Walinga equipment, from the smallest 506 through to the largest 1020 models, customers can select a field proven blower matched to most any application. See chart below for specification comparison.

Remember, if you have any questions at all, you are invited to speak with a Walinga representative by live 'Chat' located at lower edge of your screen or to call us directly.

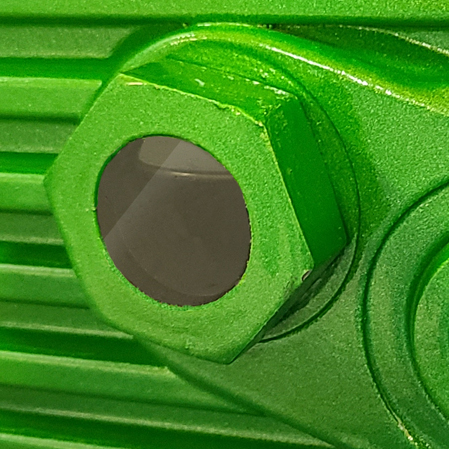

WALINGA'S Proprietary Hard Coatings

Experienced in the manufacturing of feed and grain equipment, Walinga is first for quality. Walinga blowers are fabricated from alloy castings that facilitate hardening. Walinga's proprietary Super Hardened Coating process out-performs chrome hardened finishes. The process eliminates premature wear from abrasive dust ensuring a much longer life than unhardened blowers.

SIX MONTH AMPS WARRANTY *EXTENDABLE TO ONE YEAR

The warranty period for Walinga parts shall expire six (6) months after the date of sale to the original customer; with the exception of parts purchased from a Walinga authorized Dealer. In these situations, the warranty period shall expire six (6) months after the date of sale recorded on the dealers Sales Order to their customer.

* Parts which are purchased from Walinga and installed at a Walinga service facility, a Walinga authorized dealer or a Walinga authorized service facility will qualify for a six (6) month warranty extension; bringing the total warranty period for these items to one (1) year from the date of their installation.

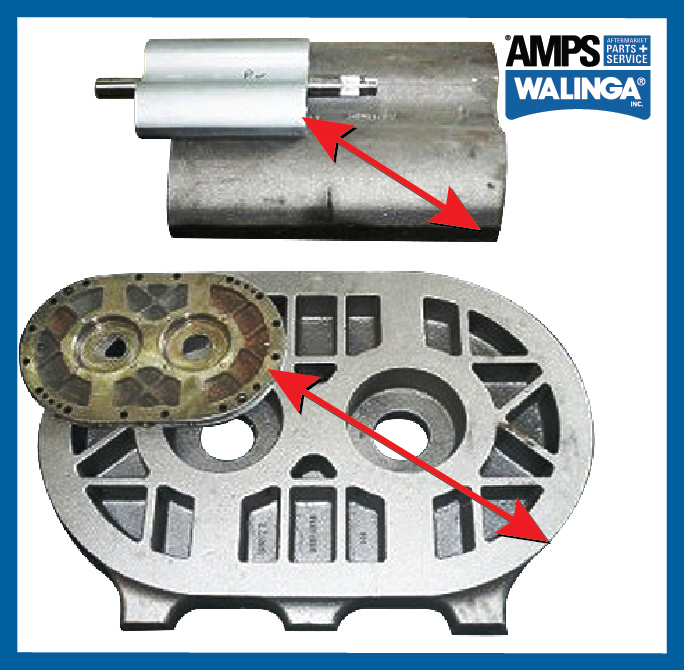

Specialty Parts are a 'Snap...'

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. If you don’t see the component you require, our engineers can make it.