Suitable for bulk transfer stations, steel mills, bakeries, food processing, chemical and other particulate manufacturing. Systems can be installed indoors or out and service multiple drops even multiple buildings. It is fully scalable, extend the system as you grow your business.

Minimize the Health and Explosive

risks associated with dust.

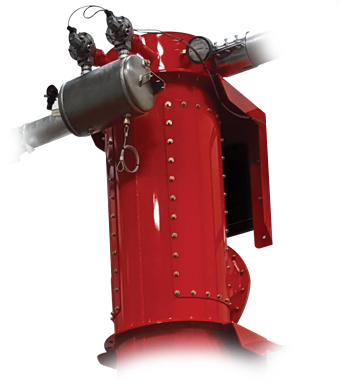

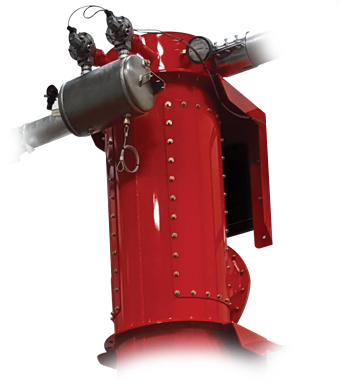

New from Walinga; a Central-Vac System featuring Air Purge Technology. This new Central-Vac System features a much smaller footprint, more consistent suction and ‘Dumpster Full’ Auto Shutdown. The

Walinga Central-Vac with Air Purge is designed

according to NFPA guidelines.

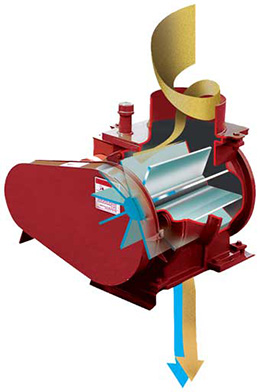

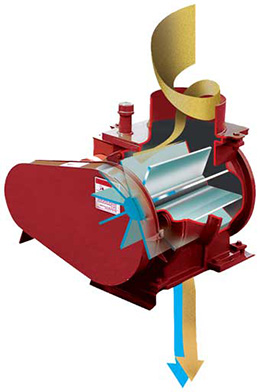

The new Air Purge Primary Cyclone combines three traditional components, the primary cyclone and bin, a secondary cyclone and bin plus filter canister into one integrated Air Purge Primary Cyclone unit.

One component replacing three means simpler installation on a smaller footprint with far less maintenance.

Design and install the system yourself. Manufactured to ISO 9001:2015 standards, parts always fit as intended, promising frustration free assembly and installation. Remember, Walinga support is always available. Tasked with simple direction, or designing turn-key systems, Walinga engineers help ensure installations are a breeze.

Is a Walinga Vac System the right choice for your transfer, dust or product recovery? It's easy enough to find out! We'll come to you. A technical representative with a full-functioning Walinga Central Vac System will visit your site, demonstrate the system with your actual bulk product and work with you to develop a system keyed to your specific needs. Call your nearest rep to arrange demo!

One Central-Vac System can handle multiple drops on multiple floors, even servicing other buildings. Both of the Walinga Central-Vac Systems may be installed indoors, outside or a utilize a practical combination of both. Rest assured that if you can pipe to it, you can connect to it.

Although they are not identical twins, the Walinga Central-Vac with Air Purge and the First Generation Central-Vac Systems share the same Walinga DNA. Both systems are covered by Walinga's Two Year / 500hr. Warranty* and share high performance Walinga Blower and Airlock components. All customers benefit from Walinga's extensive support network. Choose from online chat, person to person or dealer support. NEW - The Walinga ONSITE Service (pilot program) now delivers service technicians, tools and parts right to your facilities door**.

*Full warranty terms and conditions are available from Walinga or your local dealer. **Geographic restrictions may apply.

Walinga endeavors that new equipment be free from defects in material and workmanship. The warranty period is either two years from purchase or 500 hrs. of operation, whichever occurs first. Full terms and conditions are available from Walinga or your local Walinga dealer.

The Walinga Hard Coated SRT Blower is available in two sizes:

1100 cfm capacity Model 510

1800 cfm capacity Model 614

Walinga Hard Coated SRT Blowers are manufactured to exact specifications and quality control standards. The housing, end plates and impellers are precision machined.

Gears and bearings are "splash lubricated". For the Central Vac application, these blowers operate at very low rpms extending the life of the blowers.

As your business grows, so will your system. Choose from a growing range of component parts and assemblies. Walinga engineered parts are manufactured to ISO 9001:2015 standards. An attention to detail that ensure parts perform to specification, they fit as they should and that installations are hassle free, now and into the future.

..with Walinga's fully-integrated CAD production line. All of Walinga manufactured parts, including customized components, are stress tested in the design phase and manufactured to ISO 9001:2015 standards. Years of experience combined with full CAD integration ensures parts assemble and perform exactly as intended. If you don’t see the component you require, our engineers can make it.